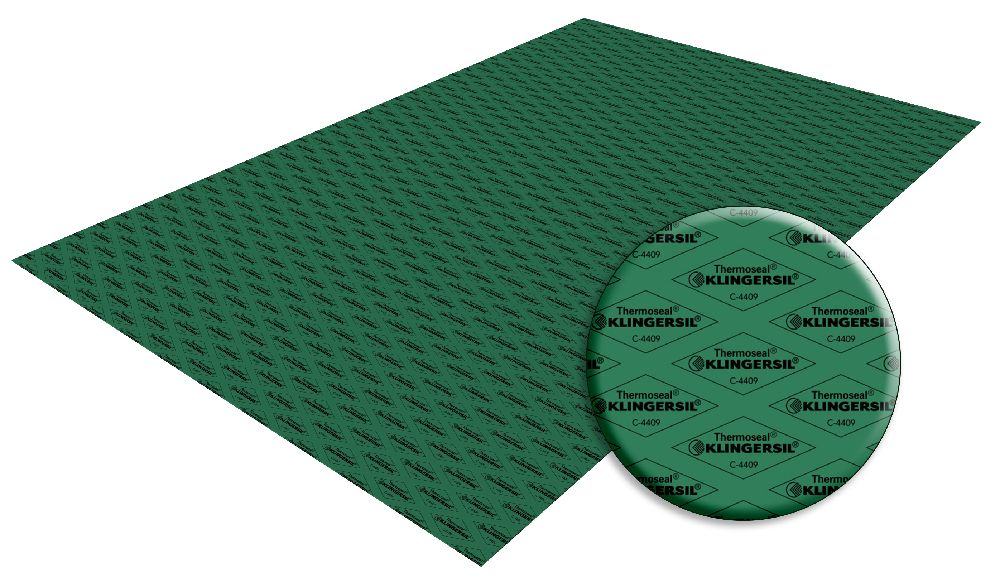

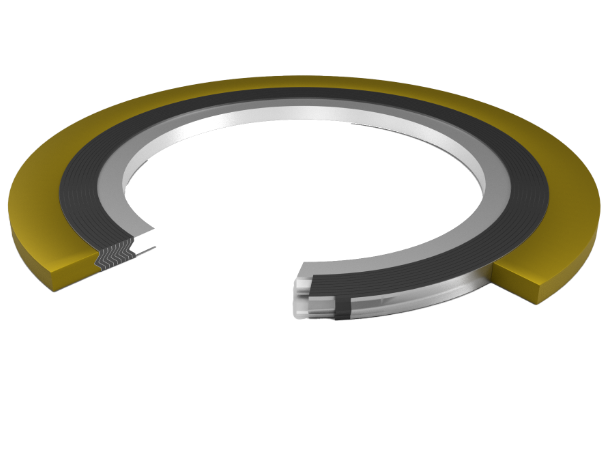

APG's C-4409 - Synthetic Fiber Sheets with Nitrile Binder has an expanded metal reinforcement. The galvanized low carbon steel insert makes this material suitable for conditions with high thermal and mechanical stress. C-4409 is excellent in hot gases and can replace spiral wound gaskets in some applications. This material is manufactured with synthetic fiber reinforced with a nitrile binder.

Benefits & Features

Performance

Suitable for hot gases

Resistant to mechanical stress

Resistant to high temperatures

Features

Expanded metal reinforcement

Synthetic fiber

Product Specifications

Typical Values Refer to 1/16'' Thick Material Unless Noted

| Creep relaxation ASTM F38B (1/32") | 20 % |

| Compressibility ASTM F36J | 6 - 12 % |

| Recovery ASTM F36J | 50 % minimum |

| KLINGER Hot Compression Test | |

| 1 Thickness Decrease 73øF (23øC) | 1 10 % initial |

| 2 Thickness Decrease 572ø F (300øC) | 2 10 % additional |

| Weight increase ASTM F146 after immersion in | |

| Fuel B, 5h/73øF (23øC) | 10 % maximum |

| Thickness Increase ASTM F146 after immersion in | |

| 1 ASTM Oil IRM 901, 5h/300øF (149øC) | 1 0 - 5 % |

| 2 ASTM Oil IRM 903, 5h/300øF (149øC) | 2 0 - 3 % |

| 3 ASTM Fuel A, 5h/73øF (23øC) | 3 0 - 5 % |

| 4 ASTM Fuel B, 5h/73øF (23øC) | 4 0 - 5 % |

| Density ASTM F1315 | 125 lb/ft (2.0 g/cc) |

| ASTM F104 Line Call Out | F712112B3E11M8 |

| Color | Green |

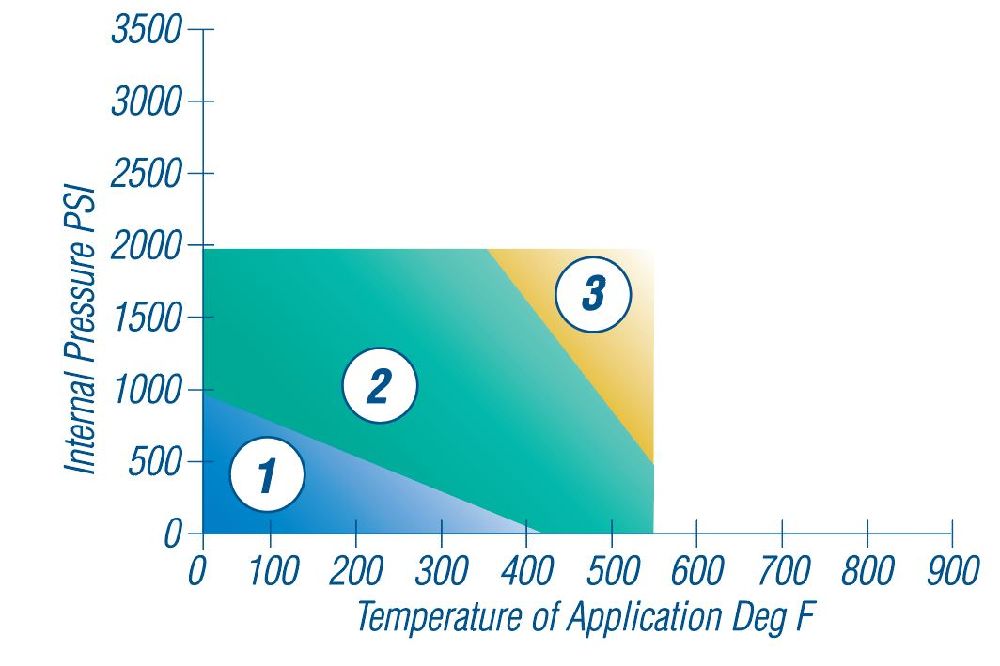

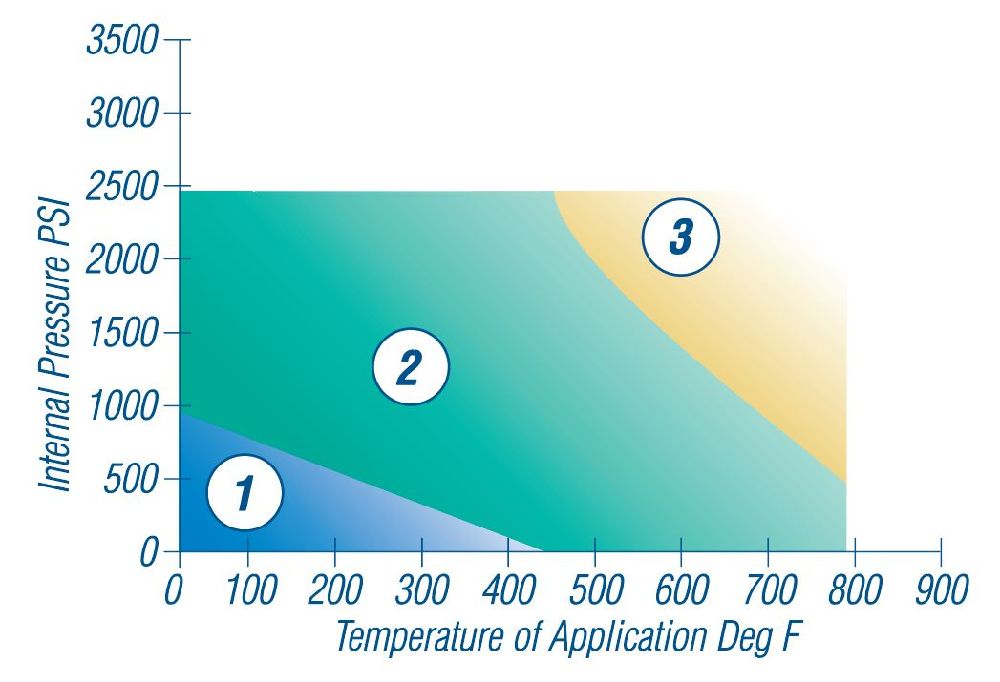

Pressure/Temperature Graphs

The pressure/temperature graphs shown are the most current method of determining the suitability of a gasket material in a known environment. However, chemical compatibility must also be considered.

pT diagram for thickness 1/16?:

Gases & Steam

Liquids

In area 1 the gasket material is suitable using common installment practices subject to chemical compatibility

In area 2 appropriate measures are necessary for installation of the gasket to ensure maximum performance.

In area 3 do not install gaskets in these applications without first contacting APG for technical support service.

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 2, Name = Sealing, SeName = sealing, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025613_footer-oring.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025613_footer-oring.png, Title = Show products in category Sealing, AlternateText = Picture for category Sealing }, SubCategoryImageId = 25613, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026399_sealing.png)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 3, Name = Industrial Couplings, SeName = industrial-couplings, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025611_footer-basic8.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025611_footer-basic8.png, Title = Show products in category Industrial Couplings, AlternateText = Picture for category Industrial Couplings }, SubCategoryImageId = 25611, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026386_industrial-couplings.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 4, Name = Industrial Glass, SeName = industrial-glass, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025615_flatfooter.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025615_flatfooter.png, Title = Show products in category Industrial Glass, AlternateText = Picture for category Industrial Glass }, SubCategoryImageId = 25615, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026400_industrial-glass.png)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 5, Name = Plastics, SeName = plastics, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025639_footer-headgear.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025639_footer-headgear.png, Title = Show products in category Plastics, AlternateText = Picture for category Plastics }, SubCategoryImageId = 25639, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026397_plastics.png)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 6, Name = Raw Materials, SeName = raw-materials, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025641_footer-cord.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025641_footer-cord.png, Title = Show products in category Raw Materials, AlternateText = Picture for category Raw Materials }, SubCategoryImageId = 25641, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026398_raw-materials.png)