APG's soft-chem - 100% Virgin PTFE Sheets provide excellent corrosion resistance and impermeability along with superior creep resistance and sealability for use in all types of applications. A proprietary manufacturing process results in a uniform and highly fibrillated micro-structure with equal tensile strength in all directions. And its superior memory characteristics ensure that bolts remain tight, so re-torquing is not necessary. The material?s high compressibility enables it to deform under load and conform to irregularities in flange faces for a tight seal with low, minimum sealing stress. Standardizing with it also helps to reduce maintenance, simplify inventory, and save money.

Benefits & Features

Features

Max Pressure: 2900 psi

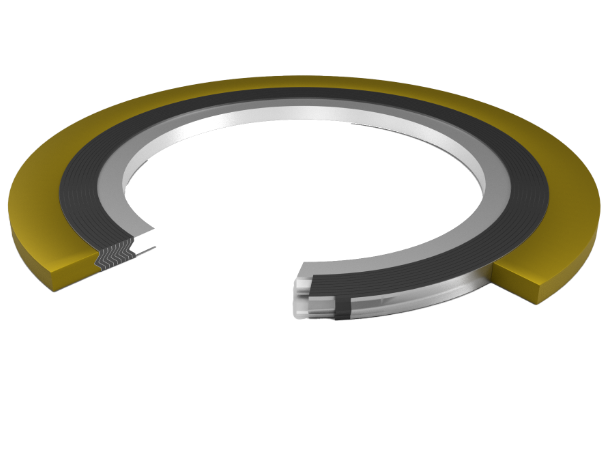

Mechanically bonded tanged stainless-steel insert

Temperature Range: -450º - 500º

Excellent resistance to chemical attack

Flexibility makes it easy to hand or die cut and simple to install

Indefinite shelf life

Dimensionally Stable

Applications

High temperature water & steam

Chemical

Alkalis / Ketones / Aldehydes

Certifications

DIN-DVGW

KTW-Guideline

Fire-safe acc. to DIN EN ISO 10497

German Llyod

- BAM tested

Product Specifications

Typical Values Refer to 1/16'' Thick Material Unless Noted

| Pressure limit | 2900 psi |

| Temperature range | -450º to 500º |

| Compressibility ASTM F36A | 45 % |

| Recovery ASTM F36A | 14 % |

| Stress relaxation DIN 52913 | 15 MPa |

| Tensile ASTM F152 | > 20 MPa |

| Density | 56 lb/ft3 (0.90 g/cm3)% |

| Color | White |

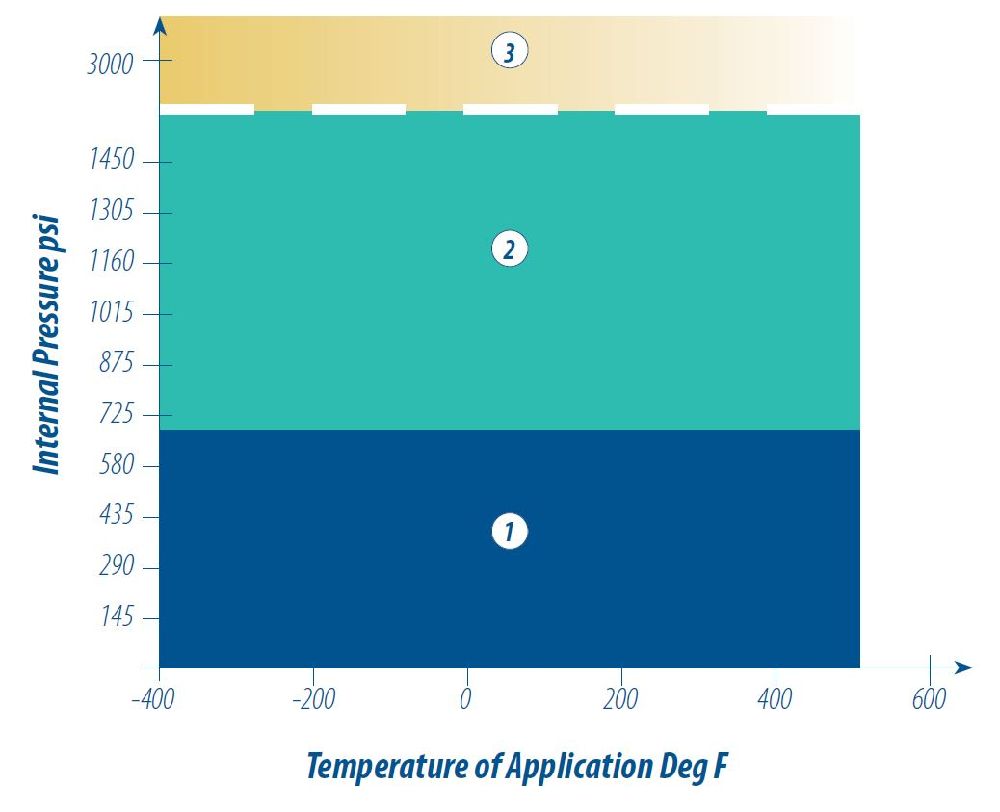

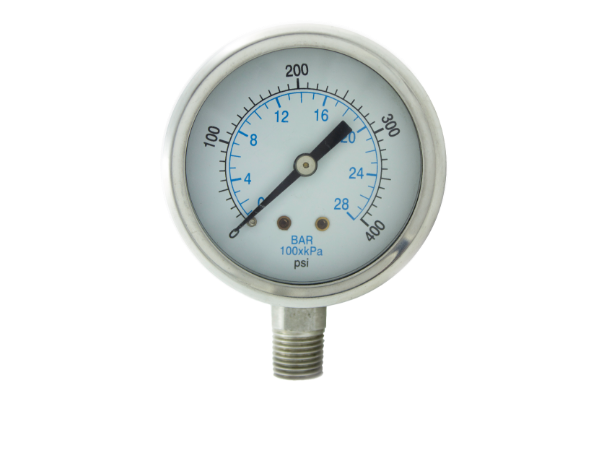

Pressure/Temperature Graphs

The pressure/temperature graphs shown are the most current method of determining the suitability of a gasket material in a known environment. However, chemical compatibility must also be considered.

IIn area 1 the gasket material is suitable using common installment practices subject to chemical compatibility

IIn area 2 appropriate measures are necessary for installation of the gasket to ensure maximum performance.

IIn area 3 do not install gaskets in these applications without first contacting APG for technical support service.

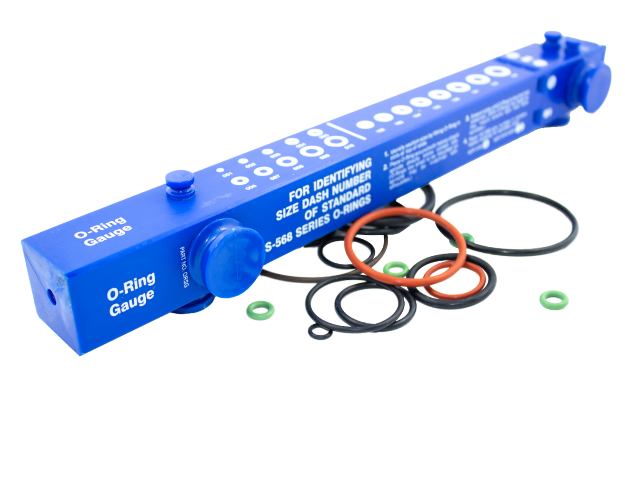

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 2, Name = Sealing, SeName = sealing, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025613_footer-oring.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025613_footer-oring.png, Title = Show products in category Sealing, AlternateText = Picture for category Sealing }, SubCategoryImageId = 25613, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026399_sealing.png)

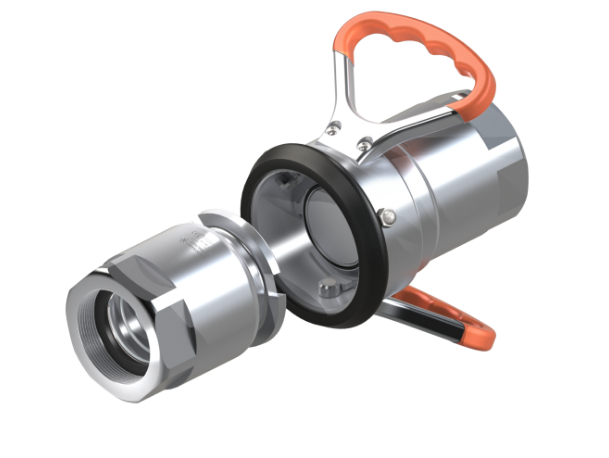

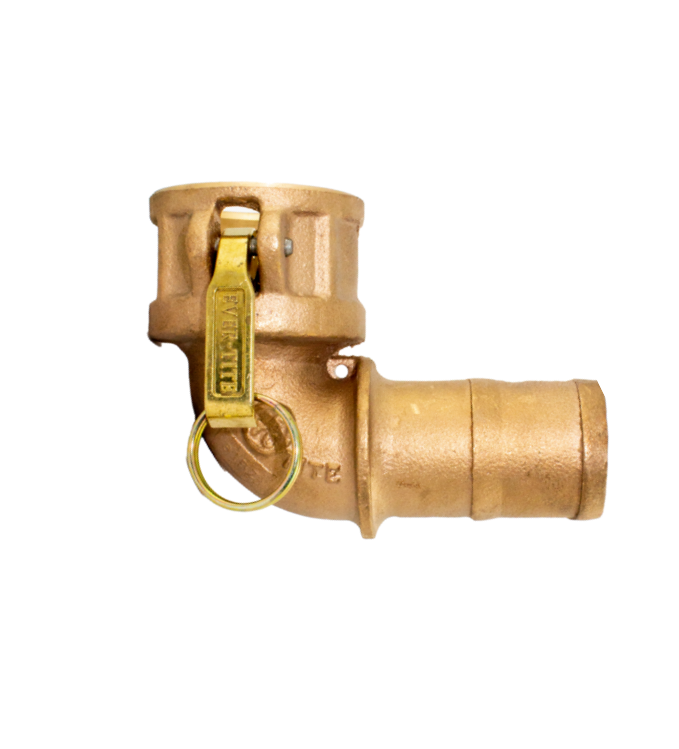

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 3, Name = Industrial Couplings, SeName = industrial-couplings, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025611_footer-basic8.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025611_footer-basic8.png, Title = Show products in category Industrial Couplings, AlternateText = Picture for category Industrial Couplings }, SubCategoryImageId = 25611, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026386_industrial-couplings.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 4, Name = Industrial Glass, SeName = industrial-glass, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025615_flatfooter.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025615_flatfooter.png, Title = Show products in category Industrial Glass, AlternateText = Picture for category Industrial Glass }, SubCategoryImageId = 25615, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026400_industrial-glass.png)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 5, Name = Plastics, SeName = plastics, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025639_footer-headgear.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025639_footer-headgear.png, Title = Show products in category Plastics, AlternateText = Picture for category Plastics }, SubCategoryImageId = 25639, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026397_plastics.png)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 6, Name = Raw Materials, SeName = raw-materials, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025641_footer-cord.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025641_footer-cord.png, Title = Show products in category Raw Materials, AlternateText = Picture for category Raw Materials }, SubCategoryImageId = 25641, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026398_raw-materials.png)