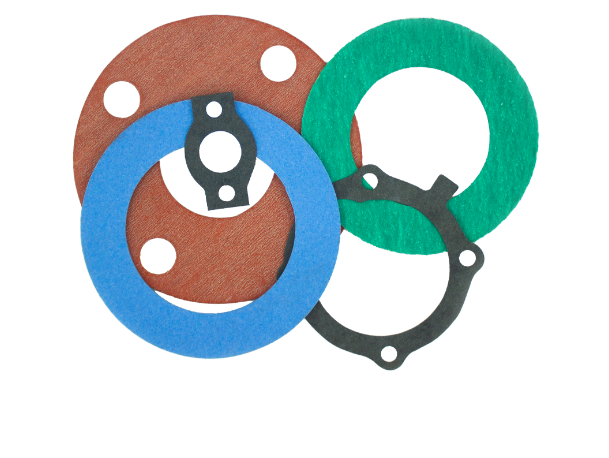

You can have the most innovative, high-tech equipment, but a poorly chosen O-ring can render it inoperable. The right O-ring in both material and size is essential for ensuring reliable performance, safety, and longevity.

Whether you're working in aerospace, oil & gas, or manufacturing, understanding how to select the correct O-ring is critical.

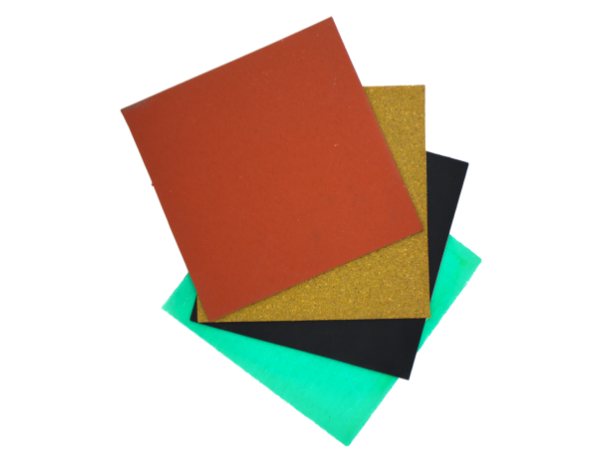

Start with Material Selection

Material selection is your first and arguably most important decision when choosing an O-ring. Different industries and environments demand different material properties.Here's a quick reference comparison:

| Material | Temp Range (ºF) | Strengths | Typical Applications |

|---|---|---|---|

| Nitrile (Buna-N) | -40 to 250 | Oil resistance, durability | Automotive, industrial machinery |

| Fluoroelastomer (FKM/Viton) | -15 to 400 | Chemical resistance, heat tolerance | Aerospace, fuel systems |

| Chloroprene (Neoprene) | -65 to 250 | Weather & ozone resistance | HVAC, refrigeration (Freon) |

| Silicone | -80 to 450 | Extreme temp tolerance, flexibility | Medical devices, lighting seals |

| Highly Saturated Nitrile (HSN) | -40 to 325 | Heat and chemical resistance | Oil & gas, transportation |

| EPDM | -65 to 300 | Steam, water, Skydrol resistance | Food-grade, aerospace hydraulics |

| PTFE | -65 to 500 | Low friction, chemical inertness | Semiconductor, pharma |

| Aflas | +25 to 450 | Electrical and chemical resistance | Power generation, chemical processing |

Tip: Start by understanding what fluids, temperatures, and movement types your O-ring will be exposed to. Match those variables to the ideal elastomeric material.

Temperature Resistance Matters

Extreme heat or cold can drastically affect O-ring elasticity and sealing performance. For example:

- In cold environments, O-rings can become brittle and crack.

- In high-heat settings, they may soften and degrade over time.

Always cross-reference your working temperature range with the material's rating to avoid premature failure.

Consider Operating Pressure

- For low to moderate pressures, a standard 70 Shore hardness works well.

- For high-pressure applications (1500+ psi), consider upgrading to a shore hardness of 80~90 to maintain shape under stress.

In dynamic systems like hydraulic pumps or piston cylinders, this change can be a make-or-break decision.

Surface Finish Impacts Longevity

For dynamic sealing applications:

- Ideal finish: 5 to 16 µin RMS

- Static sealing: Up to 64 µin RMS is acceptable

Improper surface finishes can increase friction, leading to premature wear and reduced effectiveness.

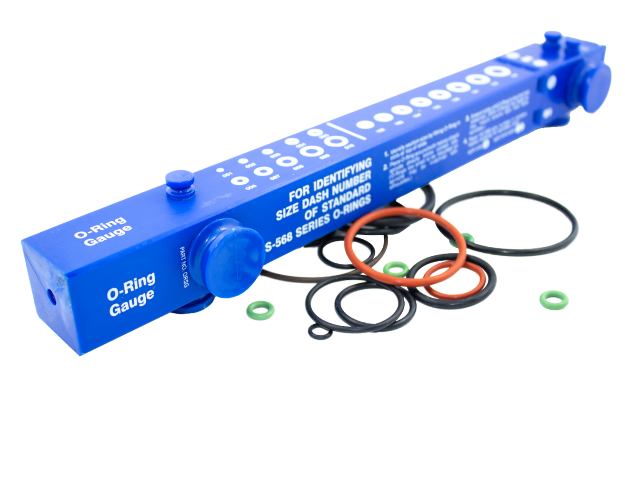

Understand Stretch and Fit

Your O-ring must sit slightly stretched in its groove to seal properly. Best practices:

- Target stretch: 2% is ideal

- Acceptable range: 1~5%

Over-stretching can distort the O-ring, while under-stretching can cause sealing gaps.

Cross-Industry Examples

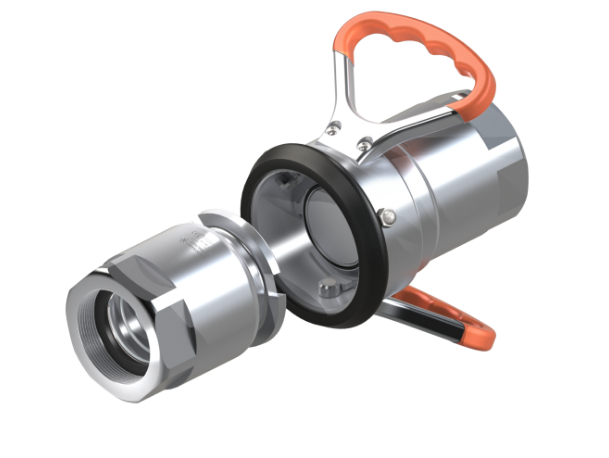

Oil & Gas, Petroleum, and Energy

O-rings in these industries must endure extreme temperatures, aggressive chemicals, and high pressures. APG offers materials like Aflas and FKM that provide excellent resistance to gas, steam, amines, and hydrocarbons - ideal for downhole tools, valves, and refinery equipment.

Semiconductor Manufacturing

Semiconductor processes demand ultra-clean, chemically resistant sealing solutions. APG's PTFE and FFKM O-rings are designed to perform in plasma etching, wet processing, and vacuum environments where contamination is non-negotiable.

Aerospace

In aerospace, precision and reliability are critical. APG supplies O-rings for use in fuel systems, hydraulic lines, and engine components, using materials like EPDM, and Vitron that meet stringent temperature and chemical exposure requirements.

Automotive

From fuel injectors and transmission systems to braking components, APG provides Buna-N and HNBR rings that deliver performance under high pressure and constant motion. Our O-rings support both traditional and electric vehicle designs.

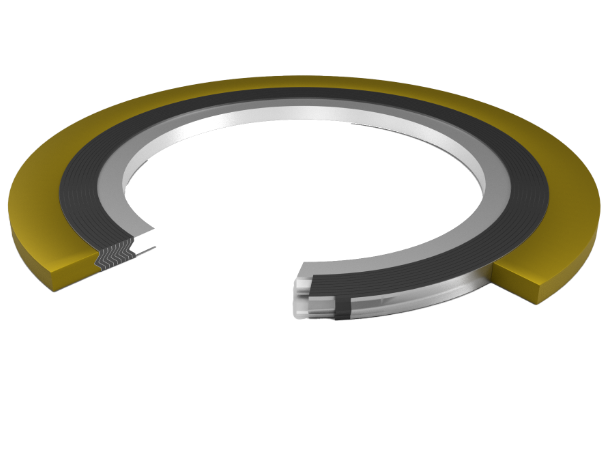

Hydraulic Systems

Sealing in hydraulic systems requires strength under pressure. APG's O-rings in NBR, HNBR, and FKM provide robust performance in cylinders, pumps, and valves where high-pressure dynamic motion is present.

Manufacturing

From robotics to automated conveyors, APG's versatile O-rings help manufacturers maintain uptime by providing dependable seals in equipment exposed to heat, vibration, and abrasive materials.

Construction

Heavy-duty equipment like excavators, concrete pumps, and compressors depend on O-rings that hold up to rough use and weather conditions. APG offers rugged, field-tested sealing options for demanding construction environments.

Chemical Processing

Safety and reliability are essential in chemical processing plants. APG's chemical-resistant elastomers ensure leak prevention in applications involving caustic fluids, acids and high temperatures.

Pulp & Paper

Wet, abrasive, and chemically treated environments are common in pulp and paper operations. APG supplies EPDM and PTFE O-rings that provide sealing in rollers, pumps, dryers, and chemical dosing equipment.

Conclusion: Choose with Confidence

Choosing the right O-ring is more than just picking a part number. It's a crucial decision that affects reliability, safety, and performance across nearly every industry.

Next Steps: Let's Help You Seal the Deal

At APG, we offer a comprehensive selection of standard and vulcanized O-rings in materials for every application. Our technical team is here to guide you through your selection process.

Browse O-Rings Now

Need help choosing? Contact an APG Expert

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 2, Name = Sealing, SeName = sealing, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025613_footer-oring.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025613_footer-oring.png, Title = Show products in category Sealing, AlternateText = Picture for category Sealing }, SubCategoryImageId = 25613, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026399_sealing.png)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 3, Name = Industrial Couplings, SeName = industrial-couplings, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025611_footer-basic8.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025611_footer-basic8.png, Title = Show products in category Industrial Couplings, AlternateText = Picture for category Industrial Couplings }, SubCategoryImageId = 25611, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026386_industrial-couplings.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 4, Name = Industrial Glass, SeName = industrial-glass, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025615_flatfooter.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025615_flatfooter.png, Title = Show products in category Industrial Glass, AlternateText = Picture for category Industrial Glass }, SubCategoryImageId = 25615, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026400_industrial-glass.png)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 5, Name = Plastics, SeName = plastics, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025639_footer-headgear.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025639_footer-headgear.png, Title = Show products in category Plastics, AlternateText = Picture for category Plastics }, SubCategoryImageId = 25639, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026397_plastics.png)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 6, Name = Raw Materials, SeName = raw-materials, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 0, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://upgrade.callapg.com/images/thumbs/0025641_footer-cord.png, ThumbImageUrl = , FullSizeImageUrl = https://upgrade.callapg.com/images/thumbs/0025641_footer-cord.png, Title = Show products in category Raw Materials, AlternateText = Picture for category Raw Materials }, SubCategoryImageId = 25641, InRawMaterials = False, RawMaterialsSubCategory = }](https://upgrade.callapg.com/images/thumbs/0026398_raw-materials.png)